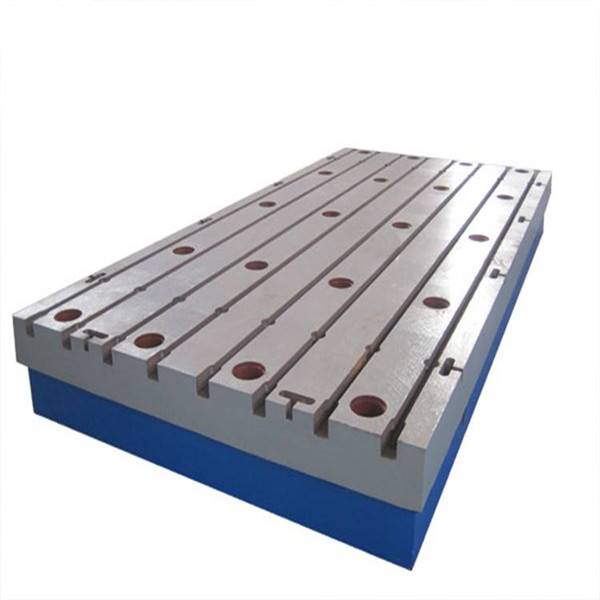

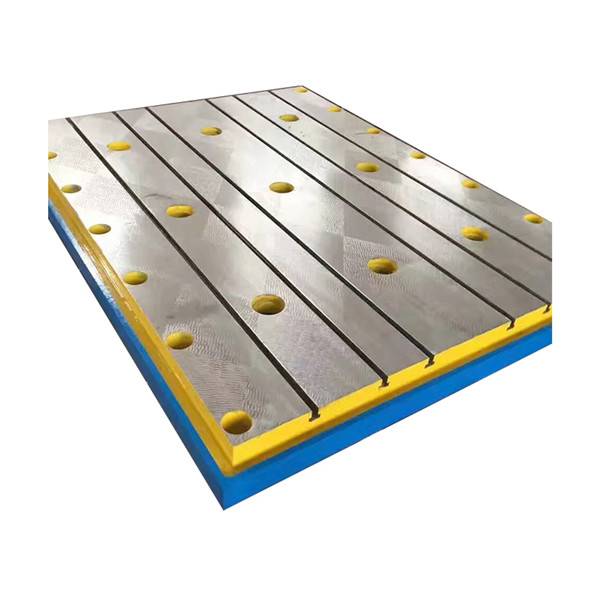

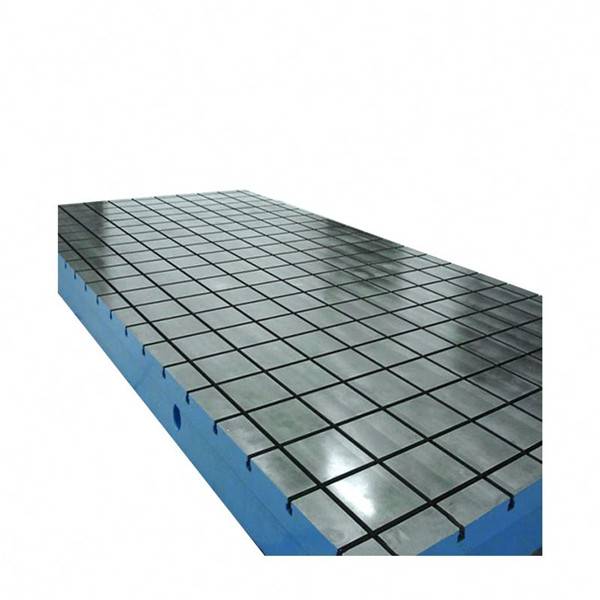

cam khwb cia hlau pem teb txaj phaj

Txais tos tuaj xyuas peb kom paub ntau ntxiv txog peb lub Hoobkas.

OEM / ODM muaj:

Koj lub logo ntawm cov khoom.

Customized khoom raws li koj cov duab kos.

Txhua yam koj lub tswv yim ntawm cov khoom peb tuaj yeem pab koj tsim thiab muab kev kos duab.

Nta ntawm peb cam khwb cia hlau pem teb txaj daim hlau

● Material is high-strength, high-density and close grained gray cast iron available at Grade of GG-20, GG-25 or GG-30 are to be chosen to manufacture the t-slotted cast iron floor plates.Lwm cov ntaub ntawv xws li nodular cam khwb cia hlau los yog cam khwb cia hlau kuj siv tau raws li kev thov;

● Lub ribbed & cored qauv muab cov hwm rigidity thiab lub zog rau t-slotted cam khwb cia hlau pem teb daim hlau.Cov qauv khoom tseem tuaj yeem muab tau raws li koj qhov kev thov.

● Hardness rau GG-25 grey cam khwb cia hlau ua t-slotted pem teb daim hlau yog nyob rau hauv thaj tsam ntawm HB170-240.Qhov chaw tiaj tus raug nyob rau saum npoo ntawm t-slotted cam khwb cia hlau pem teb daim hlau yog muaj raws li qib I, II lossis III raws li DIN 876 Standarad.Qhov siab dua qhov tseeb tuaj yeem tau txais los ntawm tes scrapping raws li koj qhov kev thov.Nto roughness ntawm t-slotted cam khwb cia hlau pem teb daim hlau feem ntau yog Ra 3.2 μm tau los ntawm kev siv cov txheej txheem CNC high-speed milling.Tsawg roughness xws li Ra 1.6 μm kuj tuaj yeem ua tiav los ntawm kev sib tsoo ntawm koj qhov kev thov;

● Qhov dav siab ntev ntawm T-slots ntawm t-slotted cam khwb cia hlau hauv pem teb daim hlau yog H12 thiab tuaj yeem yog H7 lossis H8 ntawm kev thov.Feem ntau T-slots thaum uas tig mus rau longitudinal kev taw qhia yog muab, tab sis kuj T-slots tilting mus rau longitudinal kev taw qhia muaj nyob rau hauv kev thov.Koj tuaj yeem thov rau ob qho tib si longitudinal thiab cross t-slots ntawm cov t-slotted cam khwb cia hlau pem teb daim hlau;

● Cored thiab ribbed kev tsim kho, ob zaug annealing kev kho cua sov ntawm qhov kub ntawm 600-700 ° C (qhov 1st annealing yog ua tiav tom qab casting, 2nd annealing yog ua tiav tom qab lub ntxhib machining ntawm lub phaj) thiab cov nram qab no aging kev kho mob yog siv rau ntawm cov t-slotted cam khwb cia hlau pem teb daim hlau los txo cov kev ntxhov siab rau qhov tsawg kawg nkaus, ua kom muaj kev ruaj ntseg siab thiab tswj nws qhov tseeb tsis muaj kev cuam tshuam;

● Kev sib txuas cov grooves ntawm txhua sab ntawm t-slotted cam khwb cia hlau hauv pem teb daim hlau tuaj yeem muab tau raws li kev thov kom sib koom ua ke ntawm daim hlau rau hauv ib cheeb tsam loj;

● Leveling thiab anchoring pads yog muab nrog rau daim hlau.Kev vibration absorbing caij nplooj ntoos hlav mounts kuj tsis tau muab rau ntawm kev thov;